Technical

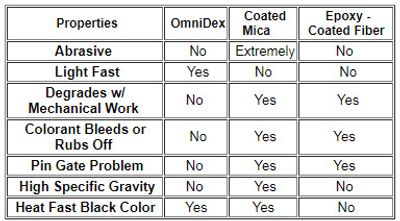

OmniDex products are a unique material as speckles. Made from a regenerated cellulosic film, they have many properties of advantage to the plastics' compounder or other polymeric processes.

The specific gravity of the speckle is close to that of polymers or water. This allows the materials to stay in supension when incorporated in liquid or molten polymer streams.

The film is not abrasive and does not exhibit tool or molding gate wear.

Color is incorporated throughtout the film and does not bleed into substrates or wear away from the incorporated surfaces of the pieces of film.

The nature of the product is finite particle size distribution giving appearances close to the streaks occuring in natural granite or other stone products.

Film nature allows for easy flow into molds and gates.

All colorants employed are on the GRAS list for FDA.

Materials exhibits a polarity useful in powder coatings and electrostatic precipitation of paint systems.

Though initial coat may seem high in comparison to other products on the market, the low specific gravity means more particles are available per pound of product giving economic advantages when coloring products.

OmniDex Compounding Aids

OmniDex materials are often difficult to "wet out" during compounding. Various agents are employed to improve the incorporation into polymeric matrices. This article offers a synopsis of the different agents employed and the "pros & cons" of the different agents employed.

Stearates are waxy compounds used to improve the wetting out of various ingredients during compounding. Compounds used in the extrusion can not contain certain levels of stearates as they create surface bubbles when the extrusion of sheet is made. For molding resin applications, most of the stearates can be employed. Care must be taken when using hindered phenolic compounds as the metal portion of the stearates may interfere with the UV stability. This is very true of zinc stearate. Calcium Stearate does not interfere with the UV stabilizers, but does not release the polymers from metal surfaces as easily.

The stearates most recommended for use with OmniDex Products is Glycerol Mono-Stearate (GMS) at levels not exceeding 5% by weight. Other Glycerol stearates may be used but are not as effective.

Mineral oils may be used to help wet out the OmniDex particulates if an ionic surfactant is used. At no time should more than 1% mineral oil be employed except in styrenic resins.

High melting waxes, such as ethylene bis-Stearmide may be used in areas where the other stearates have too Iow of a melting point.

These materials are only meant to serve as a guide for use. The end user of any product must test for compatibility of all ingredients used in their particular resin formulations.

The above Information Is provided in good faith by OmniDex Products Corporation, and is to the best of our knowledge true and accurate. However, OmniDex Products makes no warranty or representation of any kind, express or implied, regarding this information, and does not assume responsibility for any subsequent processing or compounding of its products in order to produce finished articles or components thereof.

Copyright © 2024 Omnidex - All Rights Reserved.

Powered by GoDaddy